Unlocking Efficiency: The Power of Liquid Jet Eductors

In the world of fluid dynamics and industrial processes, efficiency is a constant pursuit. One invaluable tool that often goes underappreciated is the Liquid Jet Eductor. Despite its unassuming appearance, this device plays a pivotal role in numerous industries, from chemical processing to wastewater treatment. In this blog, we will delve into the world of Liquid Jet Eductors, exploring their functionality, applications, and why they are considered indispensable in various fields.

The Science Behind Liquid Jet Eductors

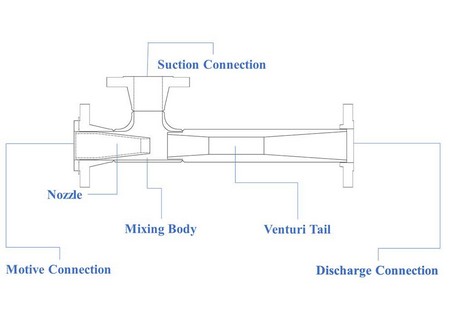

Liquid Jet Eductors, also known as jet pumps or ejectors, operate on a simple yet ingenious principle. They utilize the kinetic energy of a high-pressure fluid stream to entrain and transport another fluid, typically at a lower pressure or flow rate. This process is achieved through the Venturi effect, which creates a localized drop in pressure when a fluid accelerates through a constricted nozzle. As a result, the surrounding fluid is drawn into the flow, effectively mixing and entraining it with the primary stream.

Versatility Across Industries

Liquid Jet Eductors find their utility in a myriad of applications due to their versatility and efficiency:

Chemical Processing: In chemical manufacturing, precise mixing of various components is paramount. Liquid Jet Eductors excel in this domain by providing thorough and rapid mixing, even for viscous or abrasive fluids. They are crucial for blending, diluting, and dosing chemicals accurately.

Wastewater Treatment: Treating wastewater involves the removal of pollutants and contaminants. Liquid Jet Eductors aid in this process by efficiently transferring chemicals or air into the water stream for coagulation, flocculation, or aeration. This results in cleaner and safer effluents.

Oil and Gas Industry: In the oil and gas sector, Liquid Jet Eductors play a vital role in enhancing production processes. They are used for crude oil aspiration, gas boosting, and injecting chemicals to optimize well performance.

Food and Beverage: Mixing, homogenizing, and dissolving ingredients are common tasks in the food and beverage industry. Liquid Jet Eductors ensure that food products are consistent in taste and quality. They are employed for everything from beverage carbonation to sugar dissolving in syrup production.

Efficiency and Cost Savings

One of the most compelling advantages of Liquid Jet Eductors is their exceptional efficiency. Unlike mechanical mixers or pumps, these devices have no moving parts, resulting in minimal maintenance and operational costs. They are energy-efficient, as they harness the energy of the motive fluid, eliminating the need for external power sources. This not only reduces operational expenses but also lowers the environmental impact.

Moreover, Liquid Jet Eductors are highly adaptable and scalable. They can be customized to suit specific flow rates, pressures, and fluid characteristics. This adaptability makes them a cost-effective choice for various industries with diverse requirements.

Get the Service You Need

In the quest for efficiency and cost-effectiveness, Liquid Jet Eductors have emerged as unsung heroes across a multitude of industries. Their ability to mix, transfer, and entrain fluids with remarkable precision makes them indispensable in chemical processing, wastewater treatment, oil and gas, food and beverage, and beyond. With their low maintenance, energy efficiency, and adaptability, they continue to be a vital component of countless industrial processes. As we look to the future of engineering and fluid dynamics, the Liquid Jet Eductor will undoubtedly maintain its position as a key player in optimizing processes and driving progress.

Call for solids conveying eductors, jet exhausters, jet compressors or even liquid jet eductors, and more. Contact this team to learn about liquid jet eductors.